Visit our Offices

Burnley Wharf, Marine Parade, Southampton, SO14 5JF

Give us a Call

Send us a Message

Office Opening Hours

Mon - Friday: 8AM - 4PM

Specialist Services

Thermal Imaging

Using FLIR imaging equipment, and specialist trained personnel, we can manage general preventative maintenance checks to class approved switchboard standards

This service can prevent unwanted breakdowns or detect more serious problems such as fires or meltdown of equipment. Before undertaking a special class docking, I.M.E will sail with a vessel to undertake a full thermal image of the ship, this data is then passed on, with any appropriate recommendations

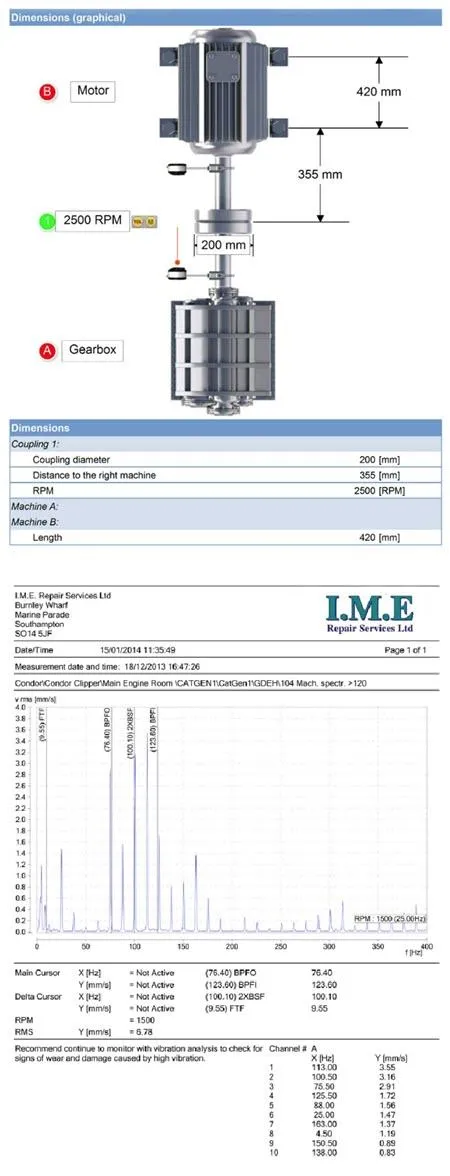

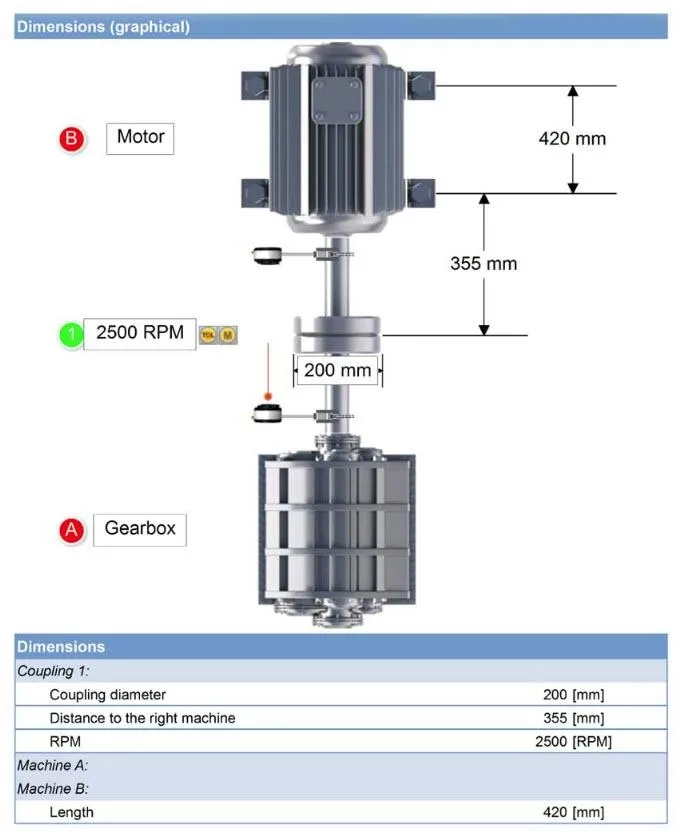

Laser Alignment

Pruftechnik smart align equipment, supporting software, accompanied with a comprehensive SKF shim kit, allows our specially trained personnel to attend your site or vessel and undertake the full alignment of your rotating equipment

This in turn, is supported with a detailed certificate of readings before and after alignment giving the customer piece of mind, that their equipment is being used at its maximum efficiency and the risk of future mechanical failure is greatly reduced

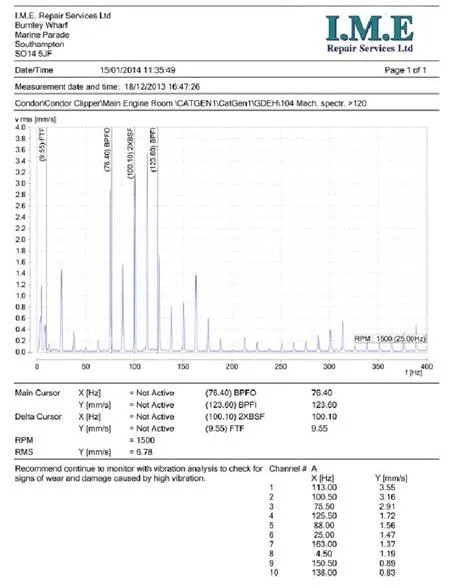

Condition Monitoring

The equipment we use, is an ‘EX’ standard, giving us the ability to work on more sensitive petro-chem sites

Monitoring your rotating equipment on a regular basis allows you to trend the condition of bearings, gears, fans etc, and plan when it is best to undertake repairs, should they be required

This prevents unwanted breakdowns which in turn could have resulted in a loss of revenue for the customer

In an age where our carbon footprint is being addressed more and more by I.M.E customers and many other large organisations, this equipment along with the laser alignment and thermal image can reduce the footprint by means of making your equipment more efficient and addressing faults in advance, allowing planned repairs to be undertaken

Our equipment also has a balancing machine software within which allows us to undertake onsite balancing should it be requested

Specialist Services

Thermal Imaging

Using FLIR imaging equipment, and specialist trained personnel, we can manage general preventative maintenance checks to class approved switchboard standards

This service can prevent unwanted breakdowns or detect more serious problems such as fires or meltdown of equipment. Before undertaking a special class docking, I.M.E will sail with a vessel to undertake a full thermal image of the ship, this data is then passed on, with any appropriate recommendations

Laser Alignment

Pruftechnik smart align equipment, supporting software, accompanied with a comprehensive SKF shim kit, allows our specially trained personnel to attend your site or vessel and undertake the full alignment of your rotating equipment

This in turn, is supported with a detailed certificate of readings before and after alignment giving the customer piece of mind, that their equipment is being used at its maximum efficiency and the risk of future mechanical failure is greatly reduced

Condition Monitoring

The equipment we use, is an ‘EX’ standard, giving us the ability to work on more sensitive petro-chem sites

Monitoring your rotating equipment on a regular basis allows you to trend the condition of bearings, gears, fans etc, and plan when it is best to undertake repairs, should they be required

This prevents unwanted breakdowns which in turn could have resulted in a loss of revenue for the customer

In an age where our carbon footprint is being addressed more and more by I.M.E customers and many other large organisations, this equipment along with the laser alignment and thermal image can reduce the footprint by means of making your equipment more efficient and addressing faults in advance, allowing planned repairs to be undertaken

Our equipment also has a balancing machine software within which allows us to undertake onsite balancing should it be requested

Client Testimonials

Thank you very much for all your efforts in carrying out the repairs on board our SD Northern River.

As always you all responded in an excellent manner and it is a pleasure working with you

Tom Cakebread

Serco

The falcon has finally managed to run up and test all systems this evening with everything going as planned; obviously we haven't been able to fully load up the deck belt but all looks good

Huge thank you to everyone involved over the last few days, it was all very last minute and I appreciate that you have had pre-existing work commitments to fulfil, so thank you very much for all the assistance

Ben Manfield

Cemex

Visit our Offices

Burnley Wharf, Marine Parade, Southampton, SO14 5JF

Main Office No

Send us a Message

About Us

Established almost 20 years, IME have become one of the most respected provider of Electrical & Mechanical Marine services in the UK

Our Services

Dockings, Refits & Repairs

Electrical Repairs & Installations

Mechanical & Engineering repairs

Coded Welding & Fabrications

Specialist Services

Office Opening Hours

Monday - 08:00-16:00

Tuesday - 08:00-16:00

Wednesday - 08:00-16:00

Thursday - 08:00-16:00

Friday - 08:00-16:00

Saturday- 08:00-12:00

Sunday - CLOSED

© Copyright 2025 - IME Repair Services Ltd | All Rights Reserved